The next floor we visited was the cutting and sewing floor . The floor is as spacious as the spinning floor, and, if one were to ask, there are as many as 100 people working here as well.

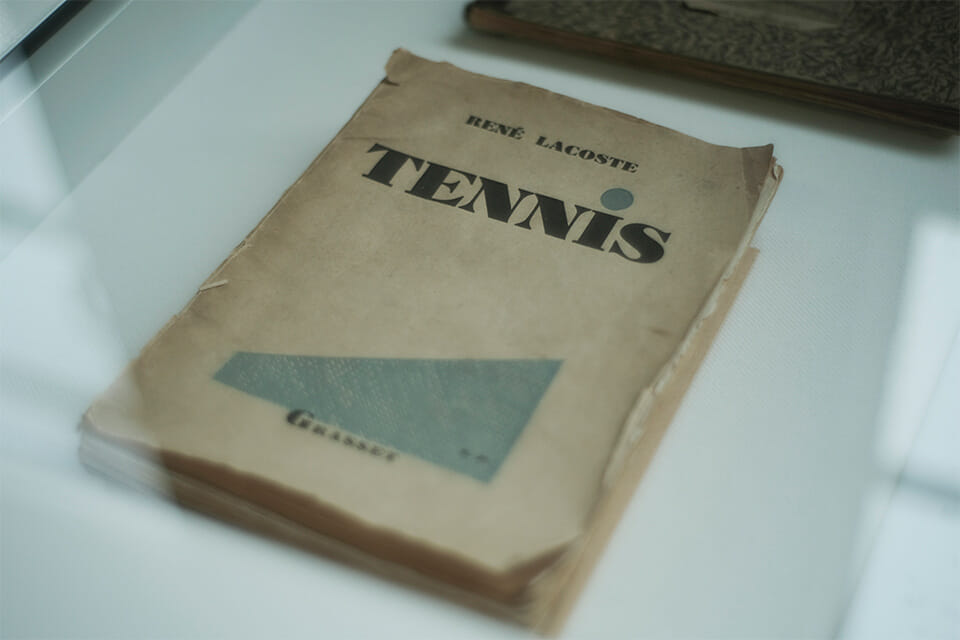

Lacoste's fabrics, which never wear out or fade, and the placket, which maintains a three-dimensional silhouette, are the two main reasons why Lacoste is so highly praised by its loyal customers.

The secret lies in the fact that the lining is 2 mm larger than the outer lining to provide a firm foundation (the lining that peeks out from underneath is called "peeking" by craftsmen). ) Because of this firmness of the front, the form of the garment does not collapse. The stitching with tubular knitted parts, not flimsy tapes, is another ingenious idea to keep the collar beautiful (you can see this at a glance when you observe them side by side. (These are obvious when observed side by side. Summer clothes are probably in the back of your closet right now, so please compare them with other brands when you change your clothes).

The difference is immediately apparent when comparing the two shirts, but Lacoste's polo shirts hardly feel loose. This is the result of the thin seam allowance structure. . However, this structure is less durable than usual. To solve this disadvantage, Lacoste uses a core yarn familiar to denim for the sewing thread. This is a polyester yarn wrapped with cotton yarn, which has outstanding strength compared to ordinary polyester spun yarn.

Lacoste's design cannot be described without mentioning the chochin sleeves, the "2" in the model's name. The construction of these sleeves, which fit snugly around the arms, prevent flapping, and also prevent perspiration, was created for tennis players, along with the slits in the sides. The slits, needless to say, are a device that does not interfere with the movement of the lower body.

As the team proceeded to the back of the factory, they noticed a space that was different from the production lines they had seen before. There were tables and chairs that could seat several dozen people, and an elderly woman was watching the women working diligently at their sewing machines.

. it is not easy to find workers, even for Lacoste. We have set up an educational institution called the Manufacturing Academy to preserve the skills we have cultivated for future generations. We will recruit about 100 people through job fairs, etc., and have them spend two years learning Lacoste's craftsmanship. The instructors are retired craftsmen.