Full-length "Mizuno Energy" and larger "Mizuno Wave".

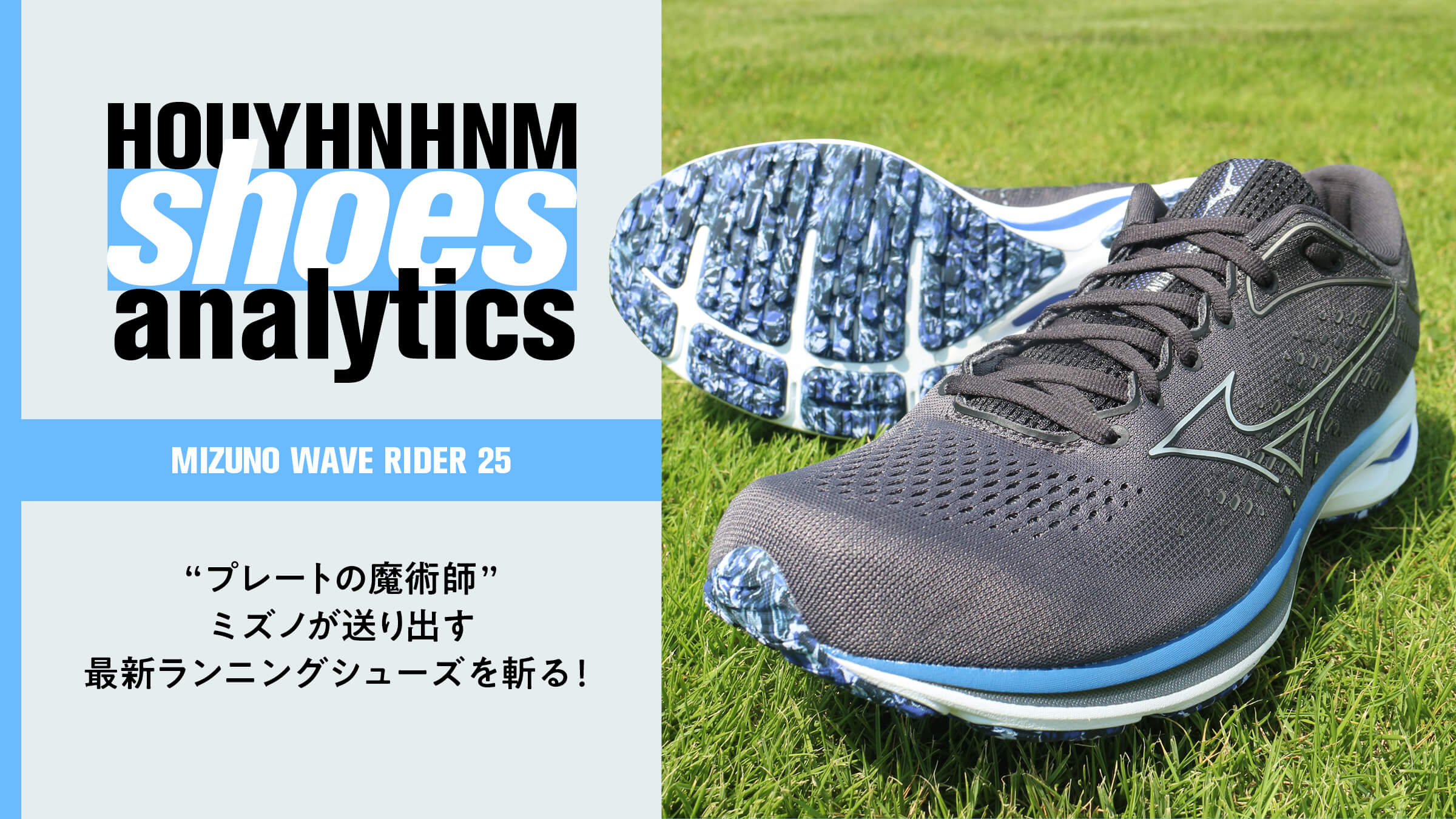

Let's take a look at the flagship model "Wave Rider 25" (level = sub 5.0 - finish) from the latest Mizuno 2021 models, with a comparison to the previous model "Wave Rider 24".

The Wave Rider 25 is a simple construction with little reinforcement.

The upper is two layers of engineered mesh. The upper of the forefoot and the upper of the shoe tongue are roughened to allow for ventilation. Compared to the previous model, the side reinforcement is less reinforced, so it has a fit that wraps around the instep. In addition, there is no stress felt from the upper when the foot bends, and the feeling is natural.

Toe comparison. The Wave Rider 25 focuses on breathability.

The tongue is a gusset tongue that is connected to the sole and fits over the entire instep. The thickness is the same as the previous model, about medium thickness. The laces are elastic for a flat strap, so even if you tighten them tightly, you will not feel a sense of pressure.

Gusset tongue connected to the sole. The white part seen behind it is the upper reinforcement.

The padding at the footwear opening is thick enough. The heel has a solid counter built in to hold the kakato in place.

In addition, the Wave Rider 25 uses recycled PET material for the laces and cuff as part of its commitment to sustainability.

The sole section has also been fully renewed. The basic structure of the midsole is the same as the previous model, with a full-length upper midsole, Mizuno Wave underneath, and the lowest midsole from midfoot to heel, while the outsole is separated from the fore to midfoot and heel sections.

The most significant topic is that "Mizuno Energy," a highly resilient sole material used in the bottom layer of the previous model, has been adopted in the upper layer as well, and the entire midsole is now of "Mizuno Energy" specifications. Mizuno Energy" is a material that is approximately 17% more flexible than Mizuno's conventional materials (compared to our company's own materials: product performance differs from material performance). (Product performance differs from material performance. Effects and feelings may vary depending on production variations, design, and other factors.) It is a material with approximately 15% higher energy return (energy return = repulsive force when the midsole material is compressed in the vertical direction). The changes to the midsole do not stop there. The grooves on the sides have also changed. You can see that the grooves on the inside of the forefoot have been eliminated, and the two grooves on the outside have been consolidated into one groove, whereas there were two grooves in the previous model.

Comparison of old and new "Mizuno Wave" from both sides.

Looking more closely, the shape and size of the "Mizuno Wave" has also been changed. In the Wave Rider 25, the length of the plate is longer and the plate covers more of the forefoot to near the heel end. In addition, the inside of the foot is extremely rolled up, which seems to strengthen the over-pronation measures.

Updated in the direction of less grooves, connecting the outsole and increasing rigidity.

The lug pattern has also been redesigned, and the inside piece, which had been divided into three pieces, has been connected into one piece. In addition, the outsole has adopted X10, which has high friction resistance in the outer part of the heel. The grooves where the midsole is exposed have also been reduced, with the aim of improving rigidity and directness.

Another area of the outsole where we felt particular attention was paid was in the edges. The outside edge, which is the first point of contact with the ground, has rounded corners for a smoother landing.

The outside edges are rounded for smooth ground contact.